0338

- Industry Water/Waste water/Desalination

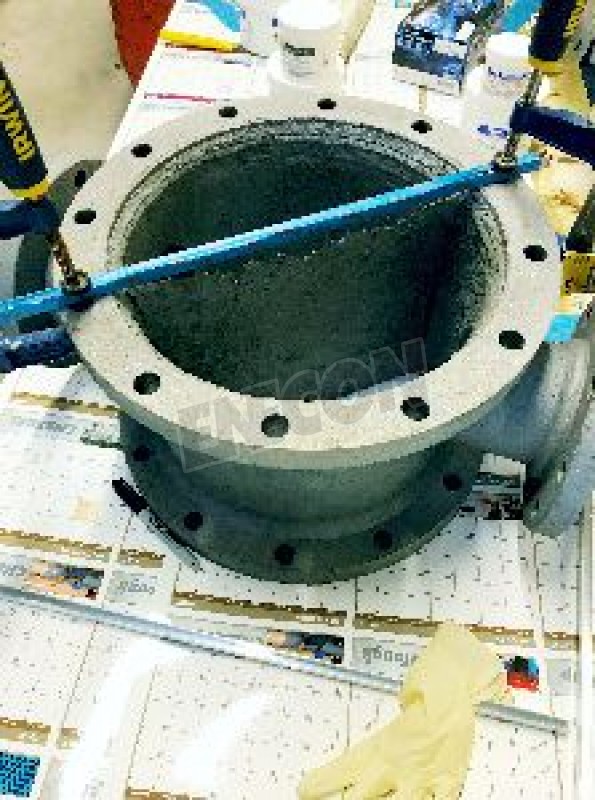

- Problem Chemical Attack, Corrosion / Erosion, and Metal Resurface

- Country United States

-

Project Goal

To repair corroded paper mill water box

- Products Used CeramAlloy CL+AC and DurAlloy

- Status Completed

The divider bar on a small, but critical, chiller water box located at a North Carolina paper mill had completely corroded and was no longer functional in the process equipment it served. The mill’s options to solve this problem were limited.

The lead time for a new water box was 5-6 weeks and the mill’s engineers were not willing to make emergency on the spot weld repairs because of safety concerns when the equipment is put back into service.

ENECON’s Distributor in North Carolina was contacted to provide a solution to this emergency situation.

The water box was degreased, pressure washed then abrasive blasted. DurAlloy and a backer plate were used to rebuild the divider bar.

One coat of CeramAlloy CL+AC in gray was used on the internal side followed by a second coat of CeramAlloy CL+AC in blue to finish the interior as well as the exterior of the water box.

The water box was completed and returned approximately 36 hours after it was first collected. The mill was very pleased with the turnaround time and outcome of the project. The repair of this essential component was approximately 30% the cost of a new water box.